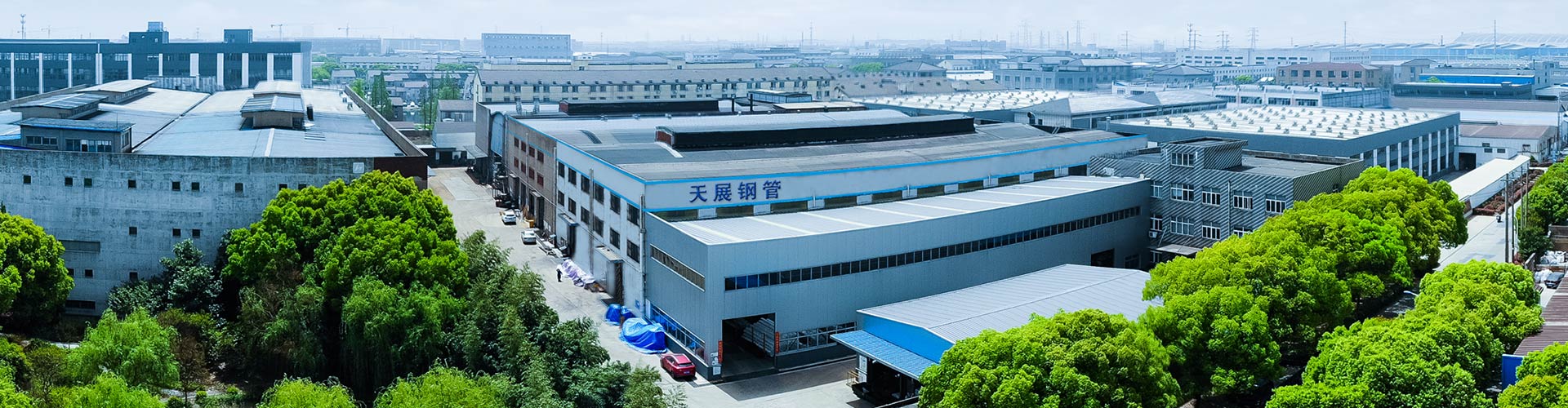

Since 2004, Tenjan Steel Tube has been a vertically integrated manufacturer of precision steel tubing. Specialize in seamless tubes, cold-drawn profiles, cold drawn welded Tube and custom-shaped steel tubes (including square, rectangular, hexagonal, and complex geometries), compliant with ASTM, EN, DIN, and JIS standards.

Our alloy and carbon steel tubes serve critical applications in automotive, high-pressure boilers, construction machinery, hydraulics, and more. With ISO-certified quality control, PMI and NDT inspections, we ensure material integrity. Offering full process control from raw material to finished product, we provide tailored, high-precision tubing for OEMs and engineering projects globally.

As a vertically integrated manufacturer, we maintain complete control from certified billet sourcing (ASTM/EN/DIN/JIS compliant) to finished tubes, ensuring uncompromised quality.

Our precision cold drawing/rolling process delivers industry-leading tolerances (±0.1mm), supported by 100% UT/ET testing and full traceability (EN 10204 3.1 certificates). We specialize in custom carbon& alloy solutions that meet the most demanding hydraulic, mechanical and energy applications, all compliant with ASTM A519/DIN 2391/EN10305 standards.

Tenjan Tube manufactures seamless carbon & alloy steel pipes meeting the strictest international standards, including ASTM (A519, A106), EN/DIN (10297, 2391,10305), and JIS (G3445) specifications.

Operating under IATF 16949 and ISO 9001 certified quality systems with third-party verification by SGS & TÜV, we guarantee full material traceability and reliable performance for precision mechanical, high-pressure, and structural applications. Every shipment includes complete mill test documentation with independent lab validation.

Precision Quality Control: 30+ Inspection Checkpoints per Steel Tube

✔ Comprehensive Quality Assurance System

- Raw Material Verification to Final Shipment Audit

- Full ASTM/EN/DIN Standard Compliance

✔ 3-Stage Inspection Protocol

① FAI (First Article Inspection)

② IPI (In-Process Inspection)

③ FI (Final Inspection)

(With digital traceability reports)

✔ Dedicated Quality Team

- 20+ Certified QC Specialists

- 12% of total workforce (vs industry avg. 5-8%)

Certified Quality & Reliability - IATF 16949 & ISO 9001 Compliant

✔ IATF 16949 Automotive Standard

Automotive-grade quality system

Strict process controls for consistency

✔ ISO 9001 Quality Framework

Internationally recognized quality management

Continuous improvement driven

✔ Advanced Non-Destructive Testing

Dual-inspection system:

• Eddy Current Testing for surface defects

• Ultrasonic Testing for internal flaws

100% inspection on critical products

60,000 MT Annual Capacity - Reliable Steel Tube Production & On-Time Delivery

✔ Massive Production Capacity

Compliant with ASTM, EN, DIN & JS Standards·20% More Cost-Efficient Solutions.

60,000+ metric tons/year ( alloy steel tube, Carbon steel tube, shaped steel tube, Cold Drawn Steel)

✔ Exceptional Delivery Performance

99.2% on-time delivery rate (tracked since 2020)

15% capacity buffer for urgent order acceleration

100+ Custom Steel Grades - Precision Tubing Solutions for Demanding Applications

✔ Material Expertise

100+ alloy & carbon steel variants

Full compliance with ASTM, EN, DIN & JIS standards

✔ Precision Dimensional Range

Outer diameter: 10-108mm (0.39"-4.25")

Wall thickness: 1-20mm (0.04"-0.79")

Tolerance: ±0.05mm (Custom round/profile tubes)

✔ Engineered Efficiency

20% lower total cost of ownership vs industry average

DFM optimization included

2,000+ Global Clients - ISO & IATF Certified Steel Tube Supplier

✔ Certified Quality Excellence

ISO 9001:2015 & IATF 16949 certified

Third-party verified by TÜV & SGS

✔ Global Client Network

2,000+ active clients across 20+ countries

Preferred supplier to automotive & machinery leaders

21 Years of Full-Service Steel Tube Solutions - Design to Delivery Guaranteed

Your Trusted Partner for Precision Engineered Tubing – Custom R&D, Manufacturing & Logistics

✔ Custom Design & DFM Optimization

(Free Design-for-Manufacturing Analysis Included)

✔ Precision Production with ±0.05mm Tolerance Control

(ISO 9001 & ASTM Certified Processes)

✔ Flexible Production Tiers

Fast-Track Service: 20-25 days (for standard specs)

Complex Projects: 45-60 days (custom Material/designs)

(90% on-time delivery record in past 12 months)

Company Building

Company Front Desk

Hot Performation Workshop

Cycling Pickling Workshop

Fully Automated Normalizing Furnace Workshop

Cold Rolled Workshop

Straightening Workshop

Ultrasonic&Eddy Current Flaw Detection Integrated Machine

Steel Tube Mechanical Testing Laboratory

Finished Goods Warehouse

Post-Processing Workshop for Steel Pipes/Tubes

Shipment

Home Tubes and Pipes Capabilities Case Studies Blogs About Get a Quote

Seamless Steel Tubes Special-Shaped Seamless Steel Tubes Cold Drawn Steel Profiles & Bars Cold-Drawn Welded Tubes Rebar Couplers

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining & Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap