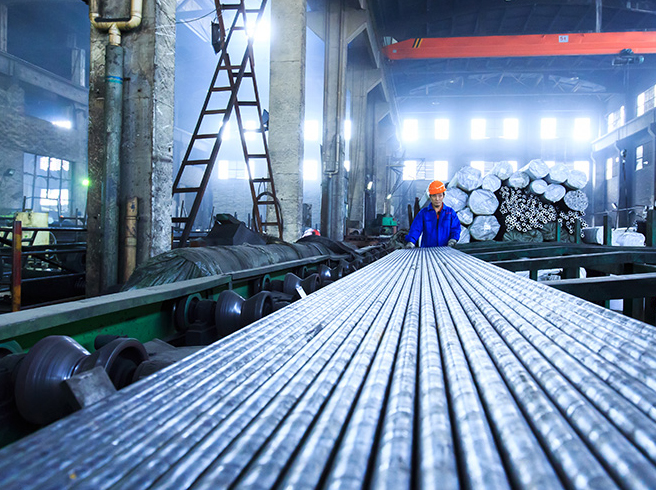

We supply high-performance steel pipes for cold drawing, cold rolling, and OEM branding, designed to reduce processing costs while ensuring precision and durability. Our pipes feature excellent cold workability, tight tolerances (±0.5% OD), and OEM-friendly services(removable laser marks, neutral packaging) to streamline your production.

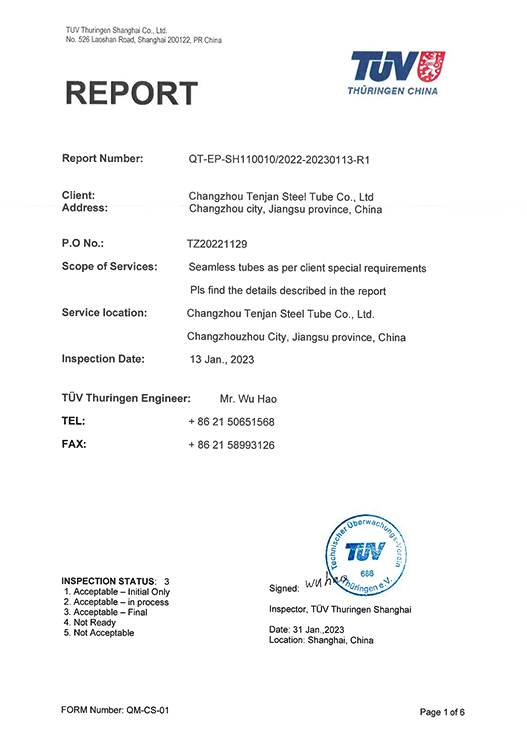

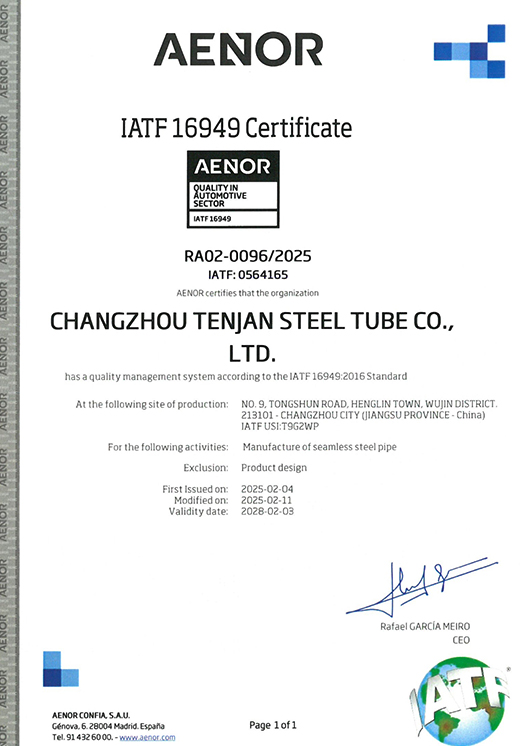

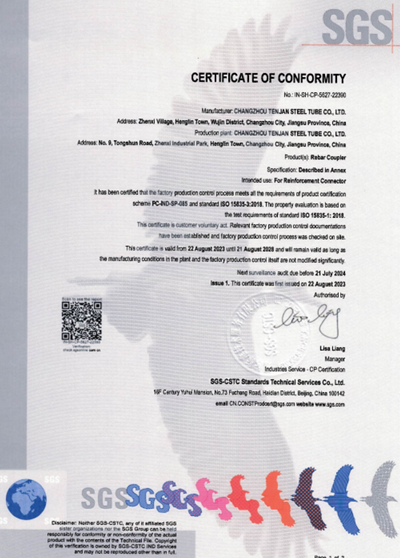

Backed by ISO 9001, IATF 16949 certifications, and SGS/TÜV test reports, they help reduce material waste by 15%+ compared to standard options. With flexible MOQs starting at 5 tons per size, we cater to global processors and distributors seeking reliable, cost-efficient steel solutions for automotive, hydraulic, machinery applications and more.

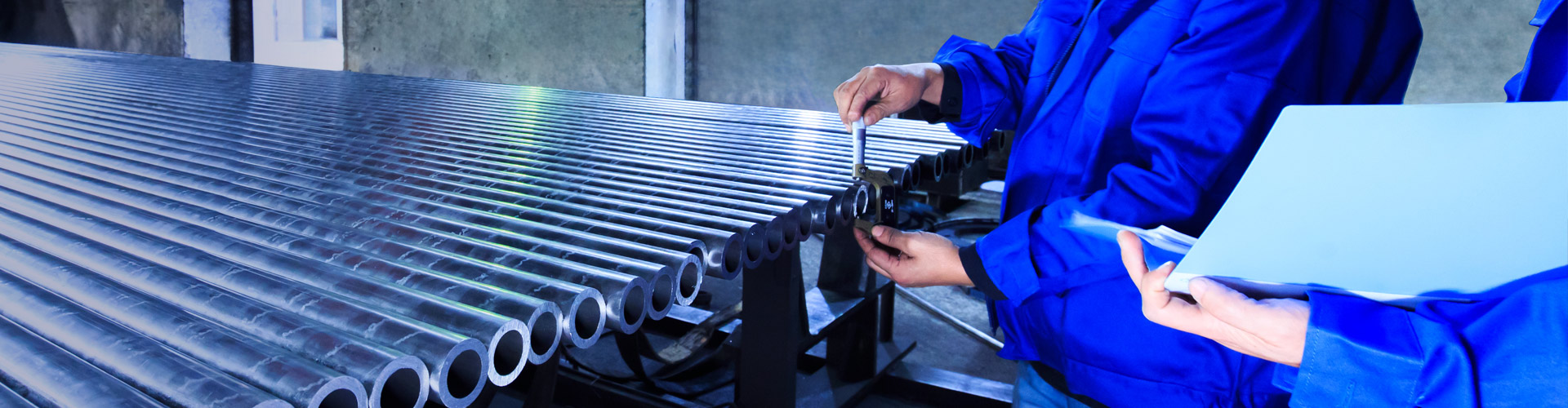

We implement strict quality control measures throughout the entire production process – from raw material inspection to final product testing. Our three-tier inspection system (First Article Inspection, In-Process Inspection, Final Inspection) ensures consistent quality standards in every batch, with full traceability and detailed inspection reports (including dimensional checks, surface quality, and performance testing). Backed by ISO 9001 & IATF 16949 certifications, we are committed to delivering high-quality products that meet your specifications and requirements.

Three-Tier Inspeciton System

Full Traceability

Detailed Inpection Report

ISO 9001& IATF 16949 Certificate

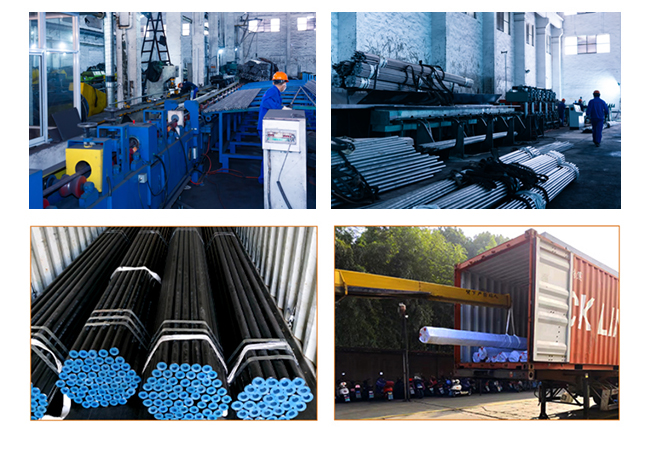

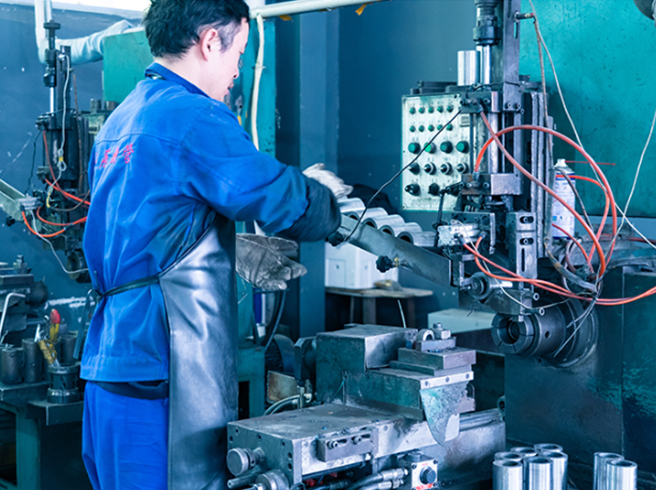

We provide complete value-added processing solutions that transform raw steel pipes into production-ready components, including precision cutting, chamfering, threading, anti-rust treatment, and export-standard packaging - all performed in our ISO-certified facilities.

These comprehensive finishing services help reduce your total costs by 15% while ensuring faster assembly and seamless global compliance with complete documentation support (MTC, packing lists, certifications).

Precision Cutting

Chamfering

Turning

Threading

Export Packaging

Export Container Loading

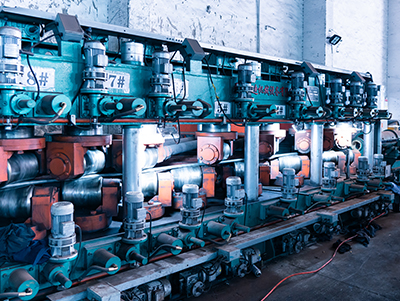

Raw Material

Perforation

Cycling Pickling

Cycling Annealing

Squeeze Head

Cold Rolling

Cold Drawing

Straightening

Ultrasonic & Eddy Current Flaw Detection

Cutting Head & Tail

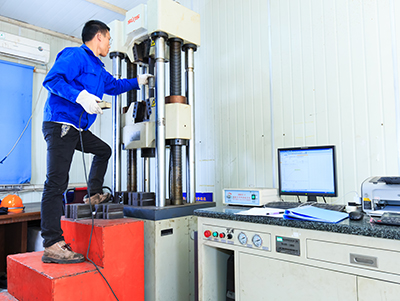

Tensile Test

Finished Product Inspection

1

Raw Material Inspection & Traceability

2

Perforation Period Inspection

3

Raw Pipe Inspection & Traceability

4

Ultrasonic and Eddy Current Flaw Detection

5

Surface Inspection on Finished Steel Tubes

6

Size Inspection on Finished Steel Tubes

7

Tensile Test

8

Chemical Composition analysis

9

Hardness Test

TUV-Test Report

IATF 16949 Automotive Quality Management System Certificate

ISO 9001 Quality Management System Certificate

ISO15835 Certificate

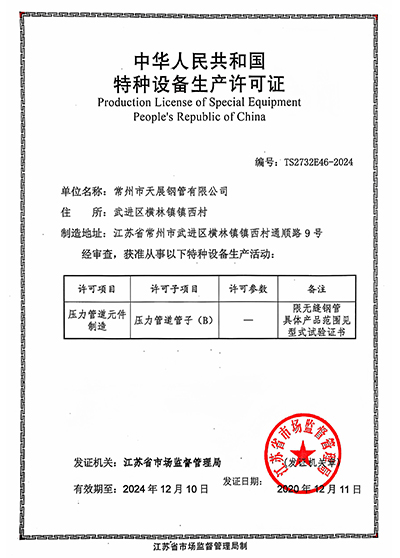

Production License of Special Equipment People's Republic of China

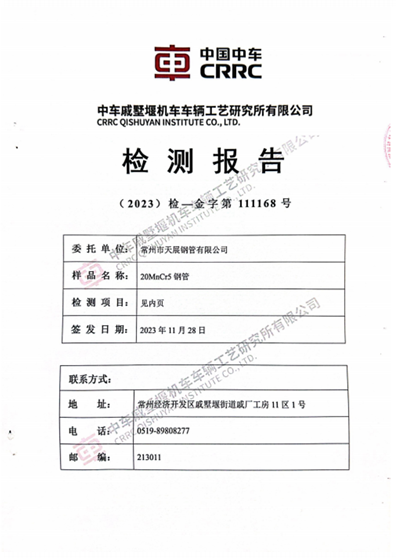

CRRC-Material Test Report

Custom-Engineered Steel Pipes – Precisely Tailored to Your Project Requirements

We deliver fully customizable steel pipe solutions designed to your exact specifications, offering flexible shapes/sizes compliant with international standards (ASTM, EN, JIS), application-specific mechanical properties, and premium raw materials sourced from certified mills (Baosteel, Shagang, Zenith Steel, etc.). Our technical team works closely with you to ensure optimal dimensional accuracy and performance characteristics for your specific applications.

Premium Quality, Optimized Cost – Maximum Value Steel Pipe Solutions

We deliver highly cost-effective steel pipes that maintain strict quality standards while offering the most competitive pricing-helping you reduce total project costs by 10-15% without compromising performance. Our lean manufacturing process and strategic raw material sourcing (from certified mills like Baosteel and Shagang) ensure consistent quality with unbeatable value, backed by ISO 9001 certification and full traceability.

Precision Quality Control – Full Traceability & Certified Excellence

We ensure controllable quality at every stage through end-to-end process traceability, IATF 16949 & ISO 9001 certified systems, and rigorous inspections (30+ processes, 60+ parameters).From raw material to finished pipes, our data-driven quality management guarantees consistent performance for critical applications.

Dedicated After-Sales Support – Quality Assurance Beyond Delivery

We provide comprehensive after-sales service, including TÜV/SGS third-party inspection support, dedicated 1-on-1 technical assistance, and proactive order tracking to ensure your complete satisfaction. Our team conducts regular follow-ups to address any concerns and optimize your product performance.

Home Tubes and Pipes Capabilities Case Studies Blogs About Get a Quote

Seamless Steel Tubes Special-Shaped Seamless Steel Tubes Cold Drawn Steel Profiles & Bars Cold-Drawn Welded Tubes Rebar Couplers

Oil & Petrochemical Industry Automotive & Motorcycle Components Mechanical Engineering Components Mining & Construction Support Structures High-Pressure Boiler System Construction Machinery Geological Drilling Agricultural Machinery Parts Industrial Fluid Transfer Systems

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap