Upsetting Parallel Thread Rebar Coupler

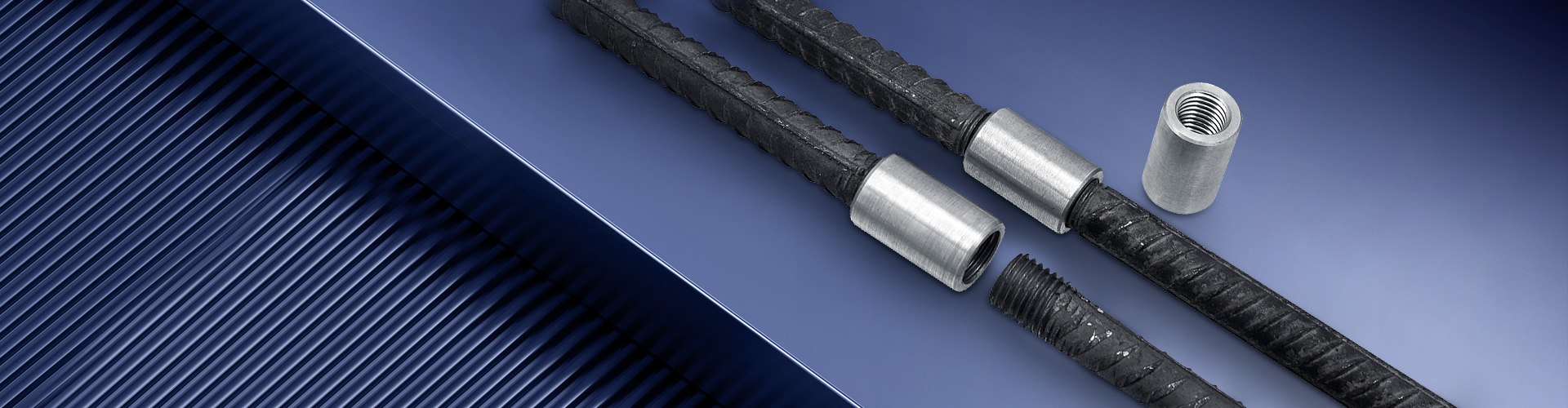

Rolling Straight Thread Rebar Coupler

Cold Extrusion Press Rebar Coupler

Bolted Rebar Coupler

Taper Thread Rebar Coupler

Customized Special Shape Rebar Coupler

1.Raw Material CustomizationOwing the entire seamless steel tube production line, Tenjan can customize rebar couplers starting from tube production according to requirement.

2.Coupler Breaking Force CustomizationBased on being an expert in material properties, Tenjan can design the rebar coupler breaking force based on the rebar standard and grade to save the overall cost for customer.

3.Standards ComplianceIn compliance with ACl318, JGJ107, UBC 1997,BS8110, NF35-20-1,DIN1045,ISO 15835.

4.Size CustomizationDesign and customize according to customers' required major diameter, pitch of thread, Length.

Tenjan Rebar Couplers are widely used in nuclear power plants, sea-crossing bridges, water conservancy dams, buildings, etc. Exported to over 20 countries across six continents, and have been consistently trusted by global customers.

Hangzhou Bay Bridge

Indonesia Jatigede Dam

Pakistan Kohala Hydropower Station

Penang Second Bridge, Malaysia

Russian Federation Tower

Zemun-Borca Bridge, Serbia

TUV Test for the seamless steel tube(the raw material of rebar coupler)

SGS Testing Report(Tensile Test-Slip Test)

Certificate-of-Approval

ISO-certificate-of-Conformity

Every batch of rebar coupler can be traced and guaranteed, following lSO9001.

Roud Bar

Tube Production

Cutting

Chamfer

Machining OD

Threading

Laser Marking

Anti-Rust

Package

Shipping

We Have A Professional Team To Provide Design+ R&D+ Customization + Customer VlP Service

1

Raw Materia Identification &Traceability

2

Seamless Steel Tube Inspection

3

Seamless Steel Tube Tensile Strength Testing

4

In-process Size Checking

5

Coupler Breaking Force Testing

6

Coupler Threading Checking(WITH GO & NO-GO GAUGE)

7

Finished Coupler Size Checking

8

Finished Coupler Surface Checking

Home Tubes and Pipes Capabilities Case Studies Blogs About Get a Quote

Seamless Steel ... Special-Shaped ... Cold Drawn Stee... Cold-Drawn Weld... Rebar Couplers

Oil & Petrochem... Automotive & Mo... Mechanical Engi... Mining & Constr... High-Pressure B... Construction Ma... Geological Dril... Agricultural Ma... Industrial Flui...

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap