Custom Sizes OD10-108mm-ASTM/EN/DIN/JIS/GOST Certified -Small-Batch Friendly

| Parameter | Key Features |

| Outer Diameter | 10-108mm (0.39"-4.25") • Fully customizable |

| Wall Thickness | 1-20mm (0.039"-0.79") • ±0.1mm precision tolerance |

| Material | Carbon Steel • Alloy Steel • Special grades available |

| Process | Cold Drawn Cold Rolled for superior finish |

| Standard | Typical Grades We Supply |

| GB | 16Mn,Q345B(Q355B),Q345C(Q355C),Q345D(Q355D),Q345E(Q355E),Q420,Q460,20Cr,40Cr, 15CrMo,20CrMo,30CrMo,35CrMo,42CrMo,20CrNiMo,40CrNiMo,20CrMnTi,20Mn2,40Mn2,40MnB,35MnB, 35Mn15CrMn,20CrMn,20CrMnMo,38CrMoAL,36Mn2V,38Mn2V,40MnMoV,15Mo3,16Mo3,31CrMoV9 |

| ASTM | Gr·50,Gr·55,Gr·65,5120,5140,4130,4135,4140,8620,4340, SAE 5120,1524,1340,15B41,SAE5115,SAE 5120,SCM23 |

| EN | E355,ST52,S355JR,S355JO,S355J2,S355NL,S420N,S420NL,S460NL,20Cr4, 41Cr4,13CrMo4-5,20CrMo4,25CrMo4,34CrMo4,42CrMo4,20NiCrMo2,34CrNiMo6, 20MnCr5,22Mn6,42Mn6,42MnB4,34MnB5,37Mn5,16MnCr5,20CrMo5. |

| JIS | SCr22,SCr440,SCM415,SCM420,SCM430,SCM435,SCM440, SNCM220,SNCM439,SMnC420H,SMn420,SMn438, SMnC420H |

| GOST | 15Г2, 09Г2C/10Г2C1,15Г2,14Г2С,C355,20Х,40X,15XM,20ХМ,30ХМ,35ХМ, 38ХМ,20ХНМ,40ХНМ,20ХГТ,20Г2,40Г2,18ХГ,20ХГМ |

| Other Speical Grades can be customized | |

| Industry | Key Applications Parts | Relevant Standards | Our Advantages |

| General Structural | Square Rectangular Tubes | GB/T 3094,ASTM A500, EN 10210 | Good Surface,lightweight,precision dimensions (±0.1mm) |

| Automotive and Motorcycle Component | Shock Absorbers,Steering Systems,Thrust Rods | EN 10305-1,JIS G3445, DIN 2391,ASTM A519 | High fatigue strength,High yield strength,lightweight, precision dimensions (±0.1mm) |

| Engineering and Mining Support | Anchor Bolts,Support Pipes,Hydraulic Props | ASTM A519,DIN 2391, JIS G3441,EN 10297-1, ISO 10799 | High Strength Yield Strength High Elongation Customization Service - Special steel grades, dimensions and surface treatments available according to project requirements |

| Construction Machinery | Drive shaft sleeves,Gearbox Guide Tubes,Crane Boom Guide Tubes,Excavator Arm Tubes,Loader Frame Tubes,Arctic Low-Temperature Tubes | ASTM A519,DIN 2391, JIS G3445,EN 10210-1, GOST 8733, ASTM A106,ISO 9329 | ID/OD tolerances of ±0.05mm. Wall thickness uniformity straightness ≤0.5mm/m |

| Fluid Transport Systems | Oil/Gas pipelines,chemical systems,Power/Energy | ASTM A106 Gr.B, EN 10216-2,GOST 8734 | Eddy Current + Ultrasonic Testing,Hydrostatic Testing |

| High-Pressure Boilers | Superheaters,Steam lines,Reheaters,Economizers) | ASTM A192,DIN 17175, EN 10216, JIS G3461/G3462 | Enhanced material density through cold-drawing/rolling ensures long-term stability Full Compliance with Int'l Standards,Superior Creep Fatigue Resistance |

| Geological Drilling | Drill Pipe,Tubing | ASTM A519,API 5DP, EN 10208-2 | High Strength Wear Resistance precision Dimensions Impact Fatigue Resistance |

| Agricultural Machinery | Hydraulic cylinders,drive shafts,Lift arms,steering housings,Boom frames | ASTM A519,EN 10210-1, DIN 2391,GOST 8733, JIS G3445 | Material Advantages:High Strength Lightweight,Precision Cold-Drawing Technology,Dimensional accuracy ±0.05mm |

| Petroleum Cracking Units | Reformer Tubes,Heat Exchanger Tubes,Reactor Feed Pipes,Transfer Lines,Quench Oil Pipes | ASTM A335,ASTM A213, EN 10216-2 | Optimized Material Purity,Precision Dimensional Control,Customized Solutions |

Tailored Features · Designed Exclusively for Your Needs

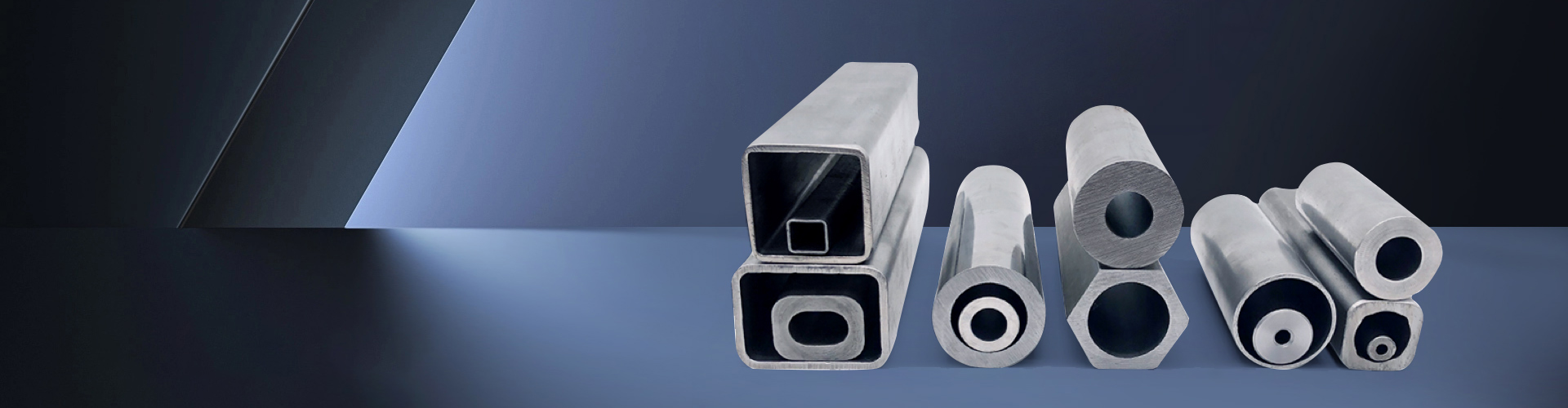

Custom-Shaped Steel Tubes – Precision Hex, Rectangular,D-Shaped & More for IndustrialComplex Cross-Section Expertise:

We specialize in precision-engineered steel tubes with custom profiles including:

✔ Standard Shapes: Hexagonal, rectangular, square, oval

✔ pecialty Profiles: D-shaped, lemon-shaped, triangular

✔ Full Customization: Tailored to your exact CAD specifications

Industry Applications:Automotive, Industrial Machinery, Agriculture Machinery,Hydraulic Systems

Special-Shaped Steel Tube Engineering – Custom Solutions for Automotive, Hydraulic Industrial Applications

Our 11+ member engineering team brings 30+ years of combined expertise in developing precision special-shaped tubes for:

✔ Automotive: Lightweight structural components, exhaust systems

✔ Hydraulics: High-pressure manifolds, precision connectors

✔ Industrial Equipment: Conveyor guides, machinery frames

✔ Energy: Heat exchanger tubing, boiler components

Precision Custom Alloy Steel Tubes – 20% Cost Efficiency with Guaranteed Performance Certified Mill Partnerships:

Collaborating with Baosteel, Xingcheng, and Shagang,we provide:

✔ 100+ Custom Alloy Grades –Tailored chemistry

(C, Cr, Mo, Ni adjustments)

✔ Engineered Properties – Yield strength 350-1200MPa customization

✔ Industrial-Grade QC – Full-spectrum testing (UT, hardness, dimensional)

Value Proposition:

✔ Verified 20% Cost Reduction – Through optimized supply chain

✔ echnical Consultancy– From material selection to application

✔ Consistent Quality – Batch-to-batch uniformity guaranteed

Advanced Heating Normalizing Technology for Precision Alloy Steel TubesInnovative Thermal Processing System:

Our extra-long piercing furnace ensures uniform billet heating, eliminating:

✓ Cracks ✓ Surface scaling ✓ Wall thickness variation

Automated normalizing furnace delivers:

✔ ±2°C temperature control– Industry-leading precision

Enhanced mechanical properties– Reliable performance for critical applications

Batch consistency– Optimized strength durability

Industry Applications:

Oil Gas, Automotive, Energy, Hydraulic Systems

Home Tubes and Pipes Capabilities Case Studies Blogs About Get a Quote

Seamless Steel ... Special-Shaped ... Cold Drawn Stee... Cold-Drawn Weld... Rebar Couplers

Oil & Petrochem... Automotive & Mo... Mechanical Engi... Mining & Constr... High-Pressure B... Construction Ma... Geological Dril... Agricultural Ma... Industrial Flui...

© 2024 Changzhou Tenjan Steel Tube Co., Ltd All rights reserved. Privacy StatementTerms-ConditionsSitemap